Introduction

Silver powder is one of the most critical functional materials in modern industry, playing a central role in electronics, energy systems, advanced coatings, and emerging technologies. Thanks to its exceptional electrical conductivity, thermal conductivity, chemical stability, and process versatility, silver powder has become indispensable in applications ranging from conductive pastes and inks to batteries, photovoltaics, and electromagnetic shielding.

As device architectures become smaller, more integrated, and more performance-driven, the demand for high-purity, morphology-controlled silver powder continues to rise. For manufacturers and researchers alike, selecting the right silver powder—with precise particle size, shape, and surface characteristics—is essential for achieving reliable performance and production efficiency.

This article provides a comprehensive overview of silver powder, including its material properties, manufacturing methods, key application areas, and critical selection criteria. It also highlights how Metalstek delivers customized silver powder solutions to meet the demanding requirements of advanced industries.

Fundamental Properties of Silver Powder

Silver (Ag) possesses a unique combination of physical and chemical properties that distinguish it from other conductive metals.

Exceptional Electrical Conductivity

Silver has the highest electrical conductivity of all metals, making silver powder the material of choice for:

- Conductive pastes and inks

- Thick-film and thin-film circuits

- Low-resistance interconnects

Even small amounts of silver powder can significantly reduce resistivity in composite systems.

Superior Thermal Conductivity

Silver’s high thermal conductivity enables efficient heat dissipation in:

- Power electronics

- LED packaging

- High-current circuit components

This property is particularly valuable in miniaturized devices where thermal management is critical.

Chemical Stability and Oxidation Resistance

Compared with copper or aluminum powders, silver powder offers:

- Excellent resistance to oxidation

- Stable electrical performance over time

- Compatibility with a wide range of organic and inorganic binders

These characteristics contribute to longer service life and improved reliability in harsh operating environments.

Processability and Morphological Control

Silver powder can be engineered into various shapes and sizes, including:

- Spherical particles

- Flake-shaped particles

- Nano-scale silver powders

This flexibility allows precise tuning of rheology, packing density, and sintering behavior.

Types of Silver Powder by Morphology

The morphology of silver powder directly affects its performance in different applications.

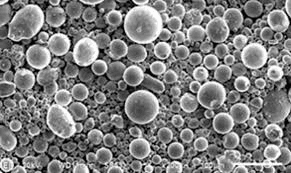

Spherical Silver Powder

Key characteristics:

- High flowability

- Uniform particle size distribution

- Good packing density

Typical applications:

- Conductive adhesives

- Powder metallurgy

- Thermal interface materials

Spherical silver powder is often preferred where smooth processing and consistent deposition are required.

Flake Silver Powder

Key characteristics:

- High aspect ratio

- Large surface contact area

- Enhanced conductivity at lower loadings

Typical applications:

- Conductive inks and pastes

- EMI shielding coatings

- Printed electronics

Flake silver powder forms efficient conductive networks, making it ideal for screen printing and flexible electronics.

Nano Silver Powder

Key characteristics:

- Particle sizes typically below 100 nm

- Low sintering temperature

- High surface energy

Typical applications:

- Low-temperature sintering pastes

- Advanced semiconductor packaging

- Printed electronics on heat-sensitive substrates

Nano silver powder enables next-generation electronic manufacturing with reduced energy consumption.

Manufacturing Methods of Silver Powder

The production method has a significant influence on particle size, purity, and surface properties.

Chemical Reduction Method

One of the most widely used techniques, chemical reduction involves reducing silver salts (such as silver nitrate) into metallic silver particles.

Advantages:

- Precise particle size control

- High purity

- Suitable for nano and micro silver powders

Common applications:

- Conductive inks

- Electronic pastes

- Research and development

Atomization Method

Molten silver is atomized into fine droplets and rapidly solidified.

Advantages:

- High production efficiency

- Spherical particle morphology

- Good flow characteristics

Common applications:

- Powder metallurgy

- Thermal and electrical materials

Electrolytic Method

Silver is deposited and collected from an electrolytic bath.

Advantages:

- High purity

- Controlled particle structure

Limitations:

- Relatively higher production cost

Key Application Areas of Silver Powder

Electronics and Microelectronics

Silver powder is a cornerstone material in the electronics industry, widely used in:

- Thick-film conductive pastes

- Multilayer ceramic capacitors (MLCCs)

- Hybrid integrated circuits

Its low resistivity and stable performance ensure reliable signal transmission and long-term durability.

Conductive Inks and Printed Electronics

The rapid growth of printed electronics has significantly increased demand for high-performance silver powder.

Applications include:

- Flexible circuits

- RFID antennas

- Touch panels

- Wearable electronics

Silver powder enables high conductivity at low curing temperatures, making it suitable for plastic and polymer substrates.

Photovoltaics and Energy Systems

In solar cell manufacturing, silver powder is used to produce:

- Front-side and back-side conductive pastes

- Current collection grids

High-purity silver powder improves conversion efficiency and reduces resistive losses in photovoltaic devices.

Batteries and Energy Storage

Silver powder plays a role in specialized battery systems, such as:

- Silver-zinc batteries

- High-reliability aerospace and defense power sources

Its excellent conductivity supports high power density and stable discharge performance.

EMI Shielding and Functional Coatings

Silver powder is commonly incorporated into coatings for:

- Electromagnetic interference (EMI) shielding

- Antistatic surfaces

- High-reflectivity coatings

These coatings are widely used in aerospace, telecommunications, and medical electronics.

Critical Selection Criteria for Silver Powder

Choosing the right silver powder requires careful evaluation of multiple parameters.

Particle Size and Distribution

- Fine powders improve conductivity but may reduce flowability

- Narrow size distributions ensure consistent processing

Purity Level

High-purity silver powder (typically ≥99.9%) is essential for:

- Electronic applications

- Semiconductor processing

- Sensitive energy systems

Surface Area and Morphology

Surface characteristics affect:

- Paste viscosity

- Sintering behavior

- Adhesion to substrates

Application-Specific Requirements

Different applications demand different silver powder specifications, including:

- Low-temperature sintering

- High aspect ratio flakes

- Controlled oxidation behavior

Metalstek’s Silver Powder Solutions

Metalstek provides high-quality silver powder engineered to meet the exacting demands of advanced industrial applications.

Key Advantages of Metalstek Silver Powder

- High purity and consistent quality

- Customizable particle size and morphology

- Stable batch-to-batch performance

- Technical support for application optimization

Customization and Technical Support

Metalstek works closely with customers to develop tailored silver powder solutions, supporting:

- Custom particle size distributions

- Specific morphology requirements

- Application-driven material optimization

Whether for conductive pastes, printed electronics, or energy applications, Metalstek’s silver powder delivers reliable performance and production efficiency.

Sustainability and Future Trends

As industries push toward sustainability and cost efficiency, silver powder technology continues to evolve.

Key trends include:

- Reduced silver loading through morphology optimization

- Development of low-temperature sintering materials

- Recycling and recovery of silver from electronic waste

Advanced silver powder design will play a crucial role in balancing performance, cost, and environmental responsibility.

Conclusion

Silver powder remains a vital material at the heart of modern electronics, energy systems, and advanced manufacturing. Its unmatched electrical and thermal conductivity, combined with excellent chemical stability and process versatility, make it indispensable across a wide range of industries.

By understanding the relationship between particle morphology, purity, and application requirements, manufacturers can unlock the full potential of silver powder. With its commitment to quality, customization, and technical expertise, Metalstek is well positioned to support customers with high-performance silver powder solutions for today’s technologies and tomorrow’s innovations.

FAQs About Silver Powder

Q1: What is the difference between flake and spherical silver powder?

Flake silver powder offers higher surface contact and conductivity at lower loadings, while spherical powder provides better flowability and packing density.

Q2: Is silver powder suitable for flexible electronics?

Yes. Especially flake and nano silver powders are widely used in conductive inks for flexible and printed electronics.

Q3: What purity levels are available for silver powder?

High-end applications typically require ≥99.9% purity, which Metalstek can supply and customize.

Q4: Can silver powder be customized for specific applications?

Absolutely. Particle size, shape, and surface properties can be tailored to meet exact application requirements.