Introduction: Rediscovering a Classic Metal in a High-Tech Era

For centuries, lead (Pb) has been viewed as an old-world material — heavy, dull, and ordinary. Yet in today’s advanced manufacturing landscape, this very metal is quietly reemerging as a high-value asset. When refined to extreme purity levels, lead transforms from a common industrial material into a precision-engineered component that supports next-generation deposition, electronics, and radiation technologies.

At Metalstek Engineering, we believe the world of high-purity materials is about rediscovery — uncovering hidden capabilities within familiar elements. Our 5N (99.999%) High-Purity Lead Metal is one such example.

Through state-of-the-art purification, processing, and quality assurance, we’ve redefined what lead can achieve for industrial and scientific customers who demand reliability, purity, and consistency above all else.

This article explores why high-purity lead is gaining attention across industries, how Metalstek ensures superior quality, and how this often-overlooked material is powering the next generation of innovation.

1. What Makes High-Purity Lead Different?

At its core, lead is valued for three things: density, malleability, and resistance to corrosion. However, when impurities are removed down to the part-per-million level, its electrical, optical, and chemical properties stabilize, unlocking new capabilities for advanced manufacturing.

Purity Levels Matter

- Standard industrial lead: typically 99.9% (3N) purity

- Refined laboratory-grade lead: ~99.99% (4N) purity

- Metalstek’s ultra-pure lead: 99.999% (5N) or higher

This leap from 3N to 5N may seem small on paper, but in the world of precision engineering, it’s transformative. Trace contaminants such as silver, bismuth, copper, or sulfur can drastically alter conductivity, oxidation behavior, or film quality during deposition. Metalstek’s advanced refining eliminates these impurities, ensuring chemical uniformity and structural consistency throughout every batch.

Key Technical Benefits of 5N Lead

- Enhanced conductivity for electronic and thin-film applications

- Superior corrosion resistance in reactive or humid environments

- Stable melting characteristics critical for vacuum deposition systems

- Uniform film growth during evaporation or sputtering processes

- Minimal gas evolution during heating, reducing contamination risk

2. The Refinement Process Behind Metalstek’s 5N Lead

Achieving 99.999% purity is not a simple matter of melting and filtering. It’s a multi-stage process requiring precision control at every step. Metalstek employs a combination of vacuum distillation, electrolytic refining, and controlled solidification to reach ultra-high purity while maintaining structural integrity.

Step 1: Raw Material Selection

All Metalstek lead feedstock originates from verified high-grade sources, typically refined from primary ores or recycled electronic materials with controlled composition. Each lot is analyzed using ICP-OES and GDMS (Glow Discharge Mass Spectrometry) to ensure starting purity meets strict internal standards.

Step 2: Advanced Purification

Using proprietary vacuum refining and electrochemical purification, Metalstek systematically removes volatile and metallic impurities. This process can lower contaminant concentrations below 1 ppm total impurities, resulting in a clean, stable material ideal for vapor-phase applications.

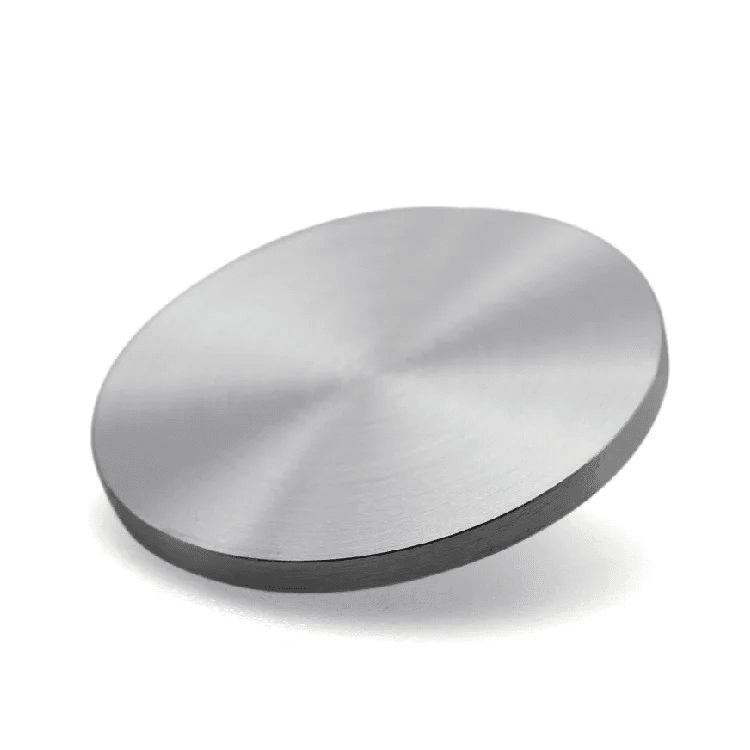

Step 3: Controlled Casting and Forming

Once purified, molten lead is cast under inert conditions to prevent oxidation. Controlled cooling ensures fine-grained uniformity and dimensional precision. For customers requiring lead sheets, plates, or sputtering targets, Metalstek provides precision machining and custom thickness control down to micrometer tolerances.

Step 4: Final Inspection and Packaging

Every batch undergoes metallographic inspection, hardness testing, and surface quality verification. The final products are packaged in vacuum-sealed or nitrogen-purged foil to prevent contamination during shipment. Certificates of Analysis (CoA) accompany all orders for traceability and compliance.

3. Why Lead Still Matters in Modern Industry

Despite its ancient history, lead remains unmatched in certain industrial characteristics. When produced in its high-purity form, it delivers value that few modern substitutes can replicate.

a. Radiation Shielding and Detection

Lead’s density (11.34 g/cm³) and atomic number (82) make it a superior barrier against ionizing radiation. In medical imaging, nuclear research, and aerospace applications, high-purity lead ensures consistent attenuation coefficients and long-term stability without chemical degradation.

Use Cases

- Protective housings for radiation detectors

- Medical diagnostic imaging systems (CT, PET, X-ray)

- Shielding components for particle accelerators or nuclear reactors

Metalstek’s 5N lead offers additional advantages — its cleanliness minimizes outgassing and microcracks, ensuring longer service life in high-radiation environments.

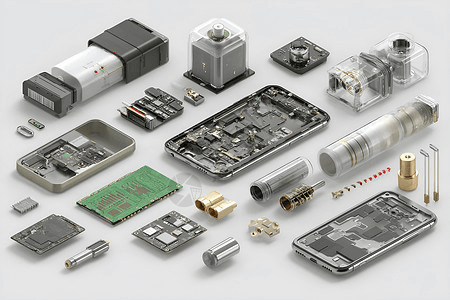

b. Deposition and Thin-Film Manufacturing

In the thin-film industry, purity directly correlates with performance. Trace elements in lower-grade lead can produce film defects, discoloration, or uneven electrical characteristics.

Metalstek’s high-purity lead is specifically engineered for use in evaporation sources, sputtering targets, and crucible materials.

Applications Include:

- Lead oxide (PbO) or lead telluride (PbTe) film deposition for thermoelectrics and infrared detectors

- Protective coatings for glass and ceramics in optical systems

- Electrode layers in capacitors and specialized sensors

The smooth melting behavior of 5N lead ensures stable vaporization rates in vacuum systems — crucial for repeatable, defect-free thin films.

c. Electronics and Semiconductor Use

While lead-free alloys dominate mainstream consumer electronics, certain high-end sectors — especially defense, aerospace, and precision sensing — continue to rely on lead’s unique combination of ductility, conductivity, and low vapor pressure.

Metalstek’s ultra-pure lead is used in:

- Special soldering applications requiring high reliability

- Vacuum tube and photonic component manufacturing

- X-ray detector assemblies and infrared sensor housings

Because our lead is free from ionic contaminants and oxides, it provides clean, conductive joints and contacts that maintain performance over decades.

d. Scientific and Research Applications

In laboratories and universities worldwide, lead’s properties make it an essential material for experimental design.

Metalstek supplies 5N lead in custom forms — sheets, foils, pellets, and machined parts — used in:

- Neutron absorption studies

- Material shielding and containment

- Crystal growth crucibles for heavy-metal oxides

Each piece is backed by full CoA data, allowing researchers to correlate purity levels with experimental outcomes.

4. Comparing Lead to Alternative Materials

Many modern metals — tungsten, bismuth, and tantalum — are sometimes proposed as alternatives for shielding or deposition. Yet, lead remains competitive due to its density-to-cost ratio, processability, and availability.

| Property | High-Purity Lead | Tungsten | Bismuth | Tantalum |

|---|---|---|---|---|

| Density (g/cm³) | 11.34 | 19.25 | 9.78 | 16.65 |

| Melting Point (°C) | 327 | 3422 | 271 | 3017 |

| Cost (USD/kg, approx.) | Low | High | Medium | High |

| Chemical Reactivity | Stable | Inert | Slightly reactive | Stable |

| Typical Use | Shielding, thin-film | Aerospace, tooling | Eco-shielding | Electronics, sputtering |

Insight: Lead’s low melting point allows low-energy processing and easy shaping, while its high density still provides superior shielding efficiency. When supplied in 5N purity, it bridges the performance gap between low-cost industrial metals and high-cost refractory materials — at a fraction of the total lifecycle cost.

5. Why B2B Buyers Choose Metalstek for High-Purity Lead

Industrial buyers seek more than just purity; they seek predictability, documentation, and support. Metalstek’s value proposition goes beyond metal delivery — it’s about partnership, performance, and proof.

a. Consistent Global Supply

With strategically located production and logistics hubs, Metalstek ensures timely supply for customers across North America, Europe, and Asia. Each shipment includes full documentation, HS codes, and export compliance details, easing international procurement processes.

b. Customization and Machining

Every industry application demands unique geometries and tolerances. Metalstek offers CNC machining, polishing, and bonding for lead sheets, foils, and targets. Typical dimensions range from 0.1 mm foils to multi-centimeter plates, all customizable upon request.

c. Certified Quality Control

- Purity verification: ICP-OES, GDMS, XRD

- Surface inspection: SEM microscopy

- Dimensional precision: laser metrology

- Certification: ISO 9001 and RoHS compliant production

Each batch comes with a Certificate of Analysis (CoA) listing impurity content, guaranteeing full traceability and reproducibility.

d. Technical Support for Integration

Metalstek’s engineering team collaborates with research labs and manufacturing facilities to optimize process compatibility. Whether you’re designing a new sputtering system or upgrading radiation shielding components, our experts provide detailed thermal and mechanical data to support your evaluation.

e. Cost-Efficiency and Lifecycle ROI

Though ultra-pure materials often come at a premium, Metalstek’s efficient refining process and bulk manufacturing scale deliver competitive pricing.

When factoring in longer lifespan, reduced maintenance, and improved deposition yields, the total cost of ownership often becomes lower than standard industrial grades.

6. Market Trends: The New Relevance of Lead in Advanced Manufacturing

a. Renewed Demand in Specialty Coatings

Recent developments in infrared sensors, optical coatings, and thermoelectric films have revived interest in lead-based materials. High-purity lead and its oxides enable stable, high-performance thin films that are difficult to reproduce with other metals.

b. Expansion in Nuclear and Medical Imaging

As nuclear medicine expands, so does the need for compact yet effective shielding materials. Metalstek’s high-purity lead is increasingly used in diagnostic equipment, laboratory chambers, and modular radiation barriers.

c. Recycling and Circular Economy

Metalstek actively supports circular economy practices by refining reclaimed lead from certified sources. Through closed-loop recovery and purification, we reduce waste while maintaining high-purity standards, aligning with customers’ sustainability goals.

7. Technical Specifications and Availability

| Parameter | Specification |

|---|---|

| Purity Level | 99.999% (5N) minimum |

| Density | 11.34 g/cm³ |

| Melting Point | 327.5 °C |

| Forms Available | Sheets, Foils, Rods, Pellets, Sputtering Targets |

| Surface Finish | Polished or Matte (as specified) |

| Packaging | Vacuum-sealed foil, inert gas optional |

| Testing Methods | ICP-OES, GDMS, XRD, SEM |

| Applications | Radiation shielding, evaporation materials, scientific research, electronics, optical coatings |

Customization:

Metalstek offers tailored dimensions, bonding options, and surface finishes based on client requirements. Lead alloys (Pb-Sn, Pb-Bi, Pb-Ag) can also be prepared upon request for specialized mechanical or thermal performance.

8. Procurement Guide for B2B Buyers

Choosing a high-purity metal supplier requires more than comparing prices. Here’s what B2B purchasers should evaluate — and how Metalstek meets or exceeds each expectation:

| Buyer Criteria | Why It Matters | Metalstek’s Advantage |

|---|---|---|

| Purity Certification | Ensures consistent performance in critical applications | CoA + 3rd-party verification available |

| Batch Traceability | Reduces risk in regulated industries | Full lot-level documentation |

| Delivery Reliability | Downtime prevention | Global logistics partners & multiple production sites |

| Technical Data Availability | Enables engineering integration | Detailed datasheets & consultation |

| After-Sales Support | Crucial for repeat projects | Dedicated technical and commercial team |

Tip: Metalstek recommends early technical consultation to ensure your deposition systems, furnaces, or reactors are matched with the correct grade and geometry of lead product.

9. Sustainability and Safety Considerations

While lead is often labeled a “hazardous” metal, its safe use in controlled industrial systems is well-documented and highly regulated. Metalstek follows all relevant safety and environmental standards to ensure responsible production and use.

- RoHS & REACH compliance: no prohibited additives or hazardous impurities.

- Sealed handling systems in processing to prevent airborne exposure.

- Recycling program: recovery of lead scrap and re-purification to minimize waste.

- Employee safety training across all facilities.

By combining technological innovation with environmental responsibility, Metalstek helps customers achieve compliance without compromising material performance.

10. Future Outlook: Lead’s Next Chapter in Modern Material Science

Lead’s image is changing. Once seen merely as a shielding metal, it’s now part of the “smart material” movement — supporting next-generation sensors, precision films, and sustainable production cycles.

As industries pursue:

- Higher-purity materials for microelectronics and optical systems

- Stable deposition sources for uniform film performance

- Compact, reliable shielding for medical and nuclear applications

High-purity lead will continue to prove indispensable.

Metalstek is investing in R&D to further refine refining techniques, explore nanostructured lead materials, and integrate digital quality monitoring systems to ensure absolute consistency across global supply chains.

Conclusion: The Smart Choice for Smart Manufacturers

In a competitive manufacturing world, where performance, purity, and predictability define success, Metalstek’s 5N High-Purity Lead represents a proven, cost-effective solution.

It’s not just a metal — it’s a material enabler that helps companies innovate faster, operate safer, and perform better.

From radiation shielding and thin-film deposition to specialized alloys and precision electronics, Metalstek’s expertise ensures every client receives a material tailored to their needs — pure, reliable, and ready for the future.

Choose purity. Choose performance. Choose Metalstek.

Related Applications & Synonyms

Applications:

- Thin film deposition

- Sputtering targets

- Evaporation materials

- Radiation shielding systems

- X-ray and nuclear instrumentation

- Thermoelectric and sensor components

- Scientific research crucibles and foils

Synonyms & Search Variants:

High Purity Lead | 5N Lead Metal | Ultra-Pure Lead | Lead Sputtering Target | Lead Evaporation Material | Radiation Shielding Lead | Electronic Grade Lead | Metalstek High Purity Metal | Pb Metal 99.999% | Lead for Thin Film Coating