When it comes to producing thin films that can handle punishing conditions, Tungsten Boride (WB) stands out as a true workhorse. Known for its exceptional hardness, extreme temperature resistance, and superior wear properties, tungsten boride sputtering targets are the go-to choice for manufacturers and researchers pushing the limits in electronics, aerospace, optics, and energy sectors.

This article explores the key benefits, applications, and specifications of tungsten boride sputtering targets, while also linking to specialized variants like WNiB and WZrB sputtering targets for niche applications.

What is Tungsten Boride (WB)?

Tungsten boride is a family of refractory compounds combining tungsten’s ultra-high melting point (over 3,400°C) with boron’s inherent hardness. The result is a dense, stable material with superior resistance to wear, oxidation, and chemical attack.

Common phases include:

- WB – Balanced hardness and conductivity.

- WB₂ – Exceptional hardness (comparable to some superhard ceramics).

- WB₄ – Extreme hardness suitable for cutting-edge protective films.

These properties make WB an outstanding material for sputtering targets used in physical vapor deposition (PVD) processes.

Advantages of Tungsten Boride Sputtering Targets

- High Hardness: Excellent scratch and abrasion resistance for protective coatings.

- Thermal Stability: Withstands high-energy sputtering and extreme substrate temperatures.

- Corrosion Resistance: Suitable for harsh chemical and oxidative environments.

- Strong Film Adhesion: Produces dense, uniform coatings with minimal defect density.

- Versatility in Applications: Compatible with DC magnetron sputtering, RF sputtering, and reactive sputtering.

Applications of WB Sputtering Targets

- Semiconductors:

- Diffusion barriers, gate electrodes, and interconnect layers.

- Aerospace & Defense:

- Heat-resistant and erosion-resistant coatings for turbine blades and nozzle components.

- Optics:

- Anti-reflective, scratch-resistant, and high-wear coatings for lenses and precision instruments.

- Energy Technologies:

- Thin-film layers in high-efficiency solar cells, fuel cells, and hydrogen energy devices.

- Tooling:

- Hard protective coatings for cutting tools, molds, and dies.

Custom Compositions – Beyond Pure Tungsten Boride

While pure tungsten boride is a powerful material, alloying can tailor its properties for specialized performance:

- WNiB Sputtering Targets: For enhanced ductility and toughness.

- WZrB Sputtering Targets: For superior corrosion resistance in harsh chemical settings.

These variants provide optimized performance in applications where standard WB may not be enough.

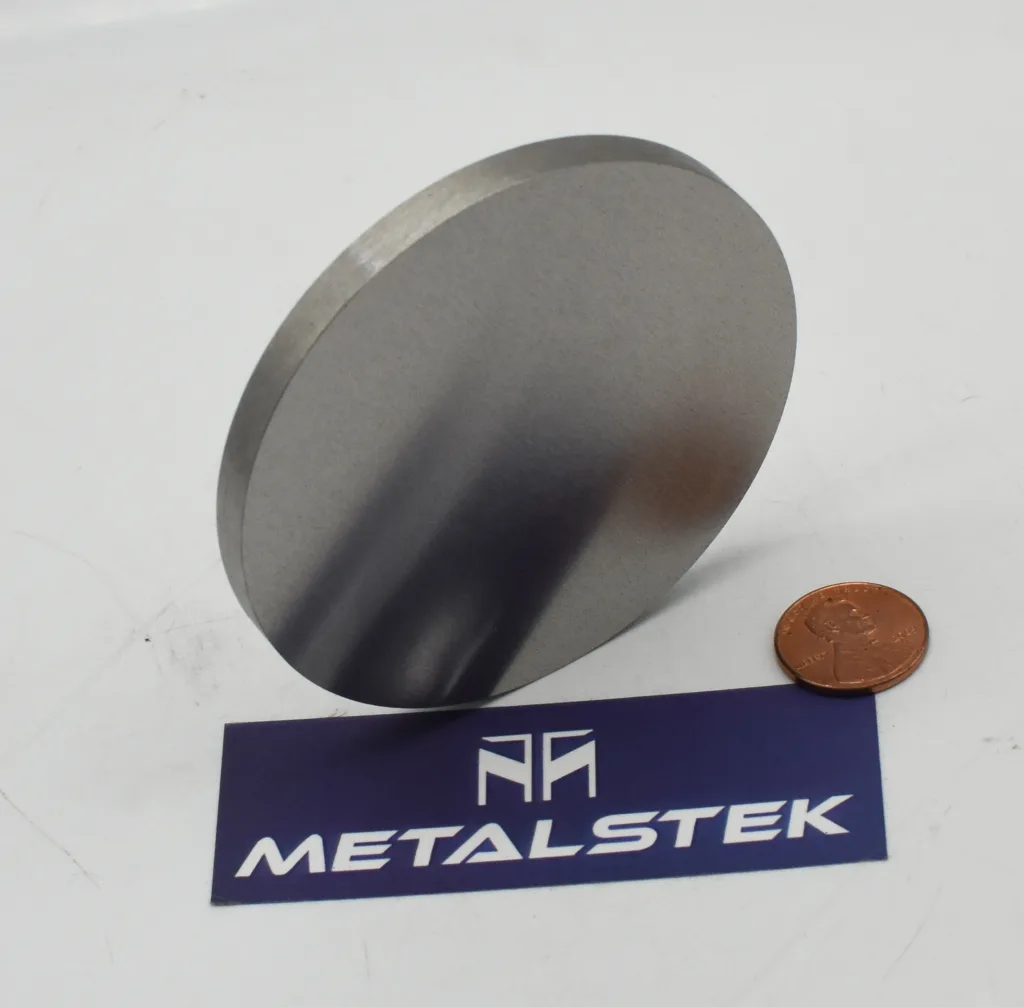

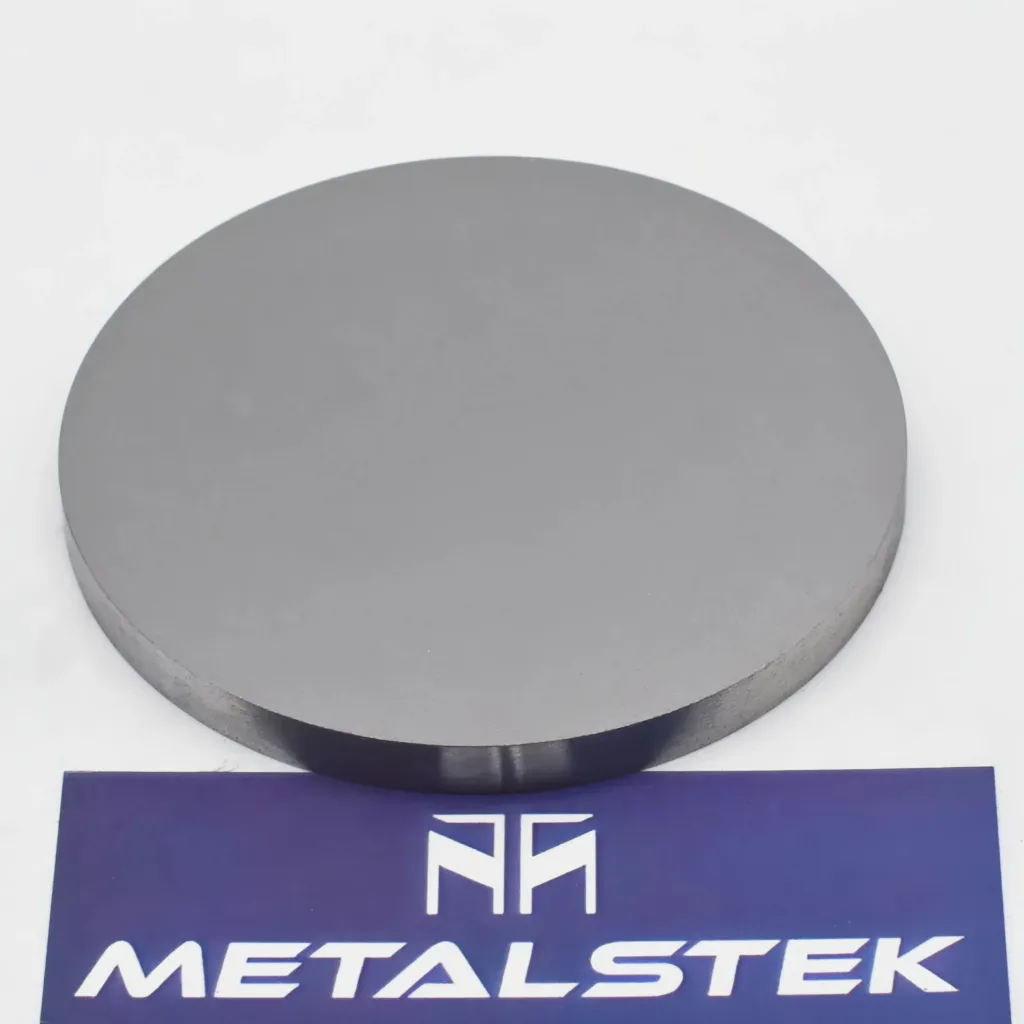

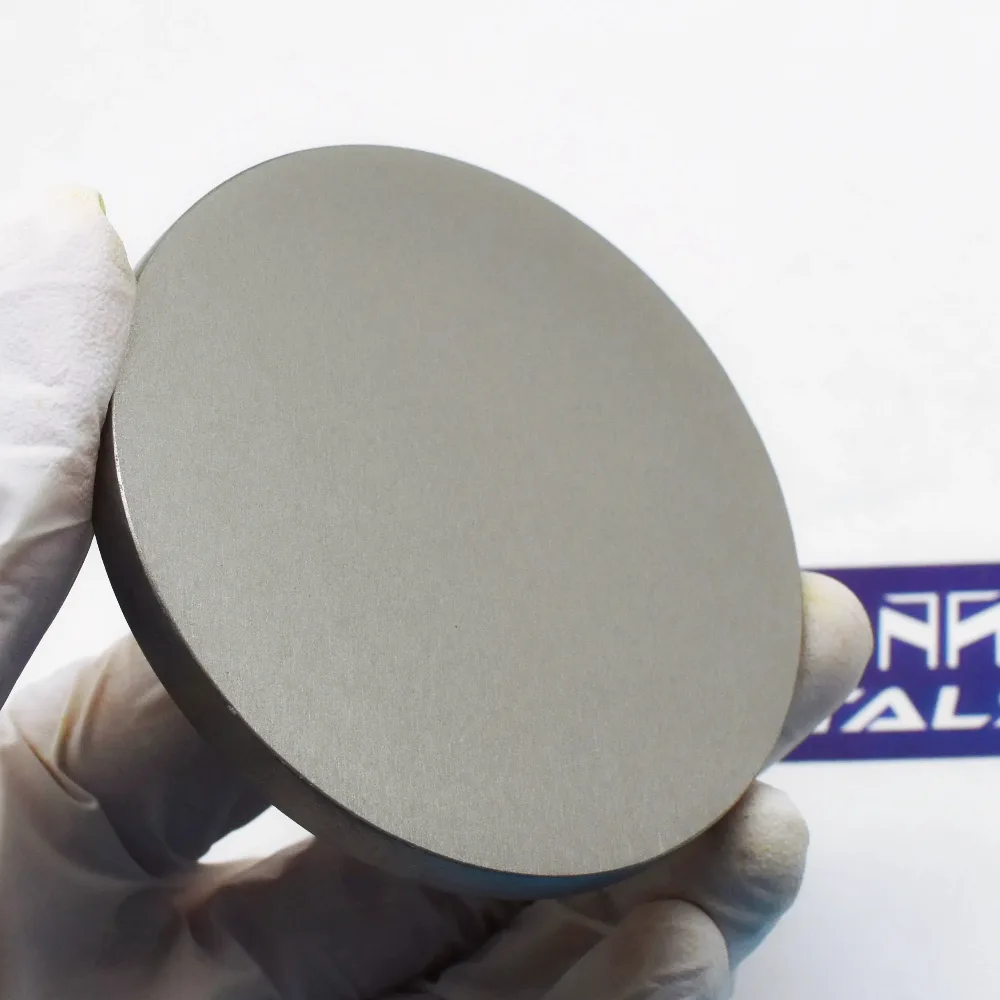

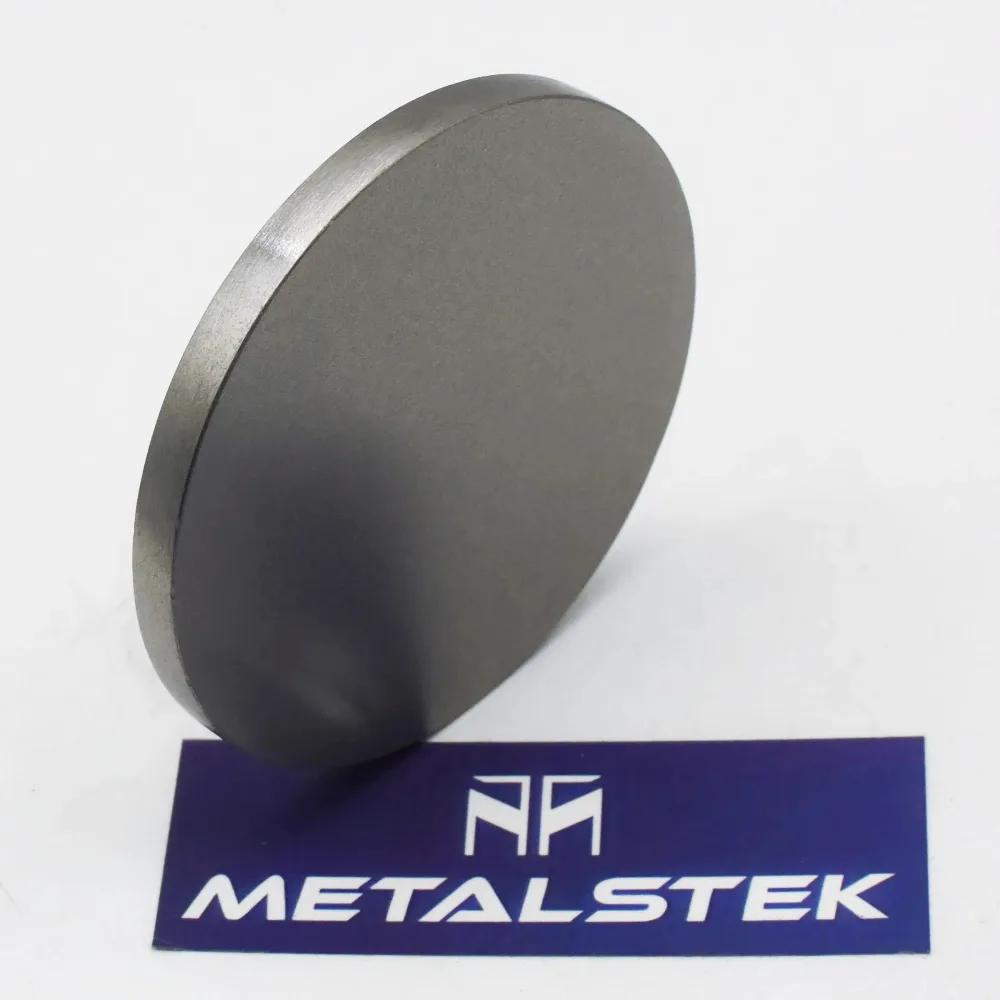

Specifications and Availability

- Purity: 99.5% – 99.99% available.

- Forms: Discs, rectangular plates, rotary targets.

- Sizes: Diameter 20–205 mm or custom.

- Bonding: Indium bonding or elastomer bonding available.

- Process Compatibility: DC magnetron sputtering, RF sputtering, and reactive sputtering.

Why Choose MetalsTek for Tungsten Boride Targets?

MetalsTek brings over a decade of expertise in refractory material manufacturing, serving clients in semiconductors, aerospace, coatings, and R&D worldwide.

We offer:

- ISO 9001-certified production.

- Custom compositions and geometries to fit any deposition system.

- Global shipping to North America, Europe, Japan, Israel, and Australia.

- Technical support from material selection to process optimization.

FAQs

Q: Can tungsten boride sputtering targets be used for optical coatings?

Absolutely. WB films are valued for their hardness and stability in precision optical applications.

Q: Do you offer WB₂ or WB₄ compositions?

Yes. We can produce specific tungsten boride phases based on your deposition requirements.

Q: How is purity verified?

Through ICP-MS and XRF testing to ensure strict quality control.

Enhance your coating performance with high-purity tungsten boride sputtering targets.

📩 Contact us at sales@metalstek.com for a custom quote or technical consultation.