Introduction: The Odd Sight That Tells a Story

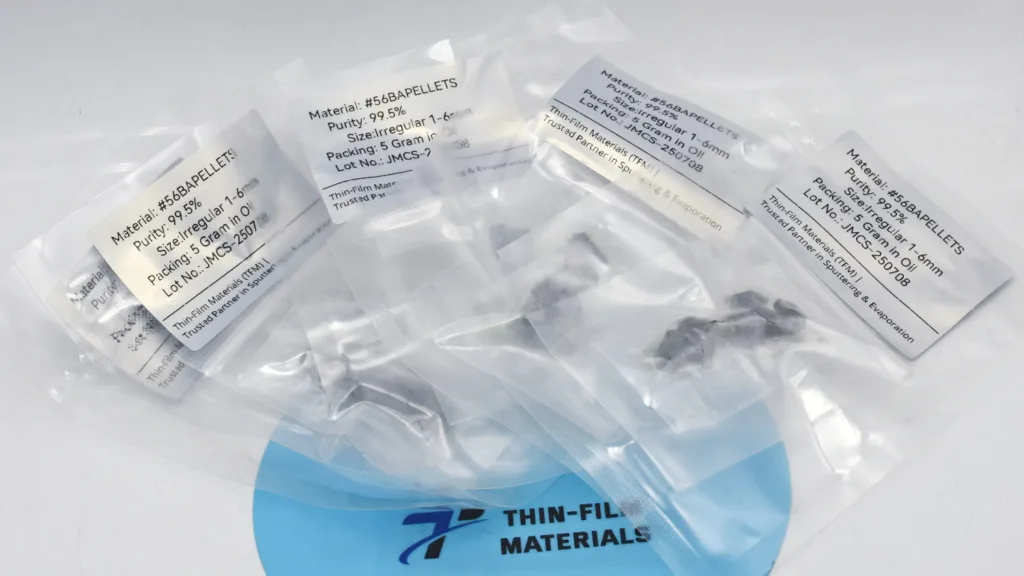

Imagine unboxing a high-purity metal product only to find it sitting in a pool of viscous, clear oil. Odd? Maybe. Unnecessary? Absolutely not. For manufacturers, researchers, and semiconductor engineers, that oily layer is a shield—guarding precious metals from oxygen, moisture, and contamination. But why is it even needed? And which metals require such treatment?

In this article, we’re breaking down the mystery of oil-packed metals and evaporation materials—why it’s done, which materials are affected most, and how to handle them properly without compromising performance.

Why Are Some Metals Packed in Oil?

Certain metals—especially high-purity or finely divided ones—are extremely reactive. In the presence of oxygen or moisture, they can oxidize, discolor, or even ignite. Oil acts as a barrier between the metal surface and the environment. Think of it as bubble wrap for chemical protection.

These are not your everyday building metals. We’re talking about the VIPs of materials science: metals used in vacuum deposition, aerospace coatings, or semiconductor fabrication. Their surfaces must remain pristine for their thin-film or high-temperature applications to succeed. Even minimal contamination can lead to failures in processes like PVD (physical vapor deposition) or CVD (chemical vapor deposition).

Which Metals & Materials Are Commonly Packed in Oil?

Here are the top metals and materials that are often shipped under oil, especially in evaporation-grade or powder forms:

- Titanium (Ti) – Prone to rapid oxidation at the surface, especially in powder form.

- Zirconium (Zr), Hafnium (Hf) – React with oxygen; used in high-purity applications like optical coatings.

- Tantalum (Ta), Niobium (Nb) – Chemically stable in bulk, but reactive as powders or nano-forms.

- Vanadium (V), Molybdenum (Mo) – High surface area powders often need oil to prevent atmospheric degradation.

- Rare Earth Metals & Alloys – Especially those with low oxidation resistance.

- Sputtering Targets & Evaporation Materials – Especially when produced in ultra-fine granule or flake forms.

Technical Considerations: What Kind of Oil Is Used?

Most manufacturers—including us at MetalsTek—use high-purity mineral oil or paraffin oil, chosen for its:

- Inert chemical behavior

- Easy removal via solvents (like isopropyl alcohol or acetone)

- No residue after proper cleaning

- Non-reactivity with high-purity metals

The oil is applied either by submersion or surface coating during final packaging. This prevents oxidation during storage and transit, especially in humid or variable environments.

Industries That Demand Oil-Packed Materials

- Semiconductor fabrication – Purity is king.

- Aerospace – Surface oxidation can compromise critical component integrity.

- Thin-film deposition labs – PVD and CVD processes are highly sensitive to contamination.

- University R&D – Experimental setups rely on consistent materials behavior.

- Coating and optical device production – Slight oxidation = major optical losses.

People Also Ask (and You Should, Too)

Q: Is it safe to store metals in oil?

A: Yes. In fact, it’s safer for reactive metals. The oil keeps oxygen and water away and can be easily removed before processing.

Q: What happens if I don’t clean the oil off before deposition?

A: You risk contamination in vacuum chambers, film defects, and compromised device performance.

Q: How do I remove oil from metal evaporation materials?

A: Soak in high-purity acetone or isopropyl alcohol, followed by vacuum drying.

Q: Can I request oil-free packaging?

A: Yes, but it’s not recommended unless you’re equipped to handle reactive materials in inert environments.

How MetalsTek Protects Your Products

At MetalsTek, we tailor each packaging process based on:

- Material reactivity

- Shipping duration

- Customer handling environment

- Final application (deposition, melting, coating)

From sputtering targets to granular evaporation pellets, we ensure your materials arrive in pristine condition—whether that means submersion in oil or vacuum-sealed pouches.

Top 10 FAQs About Oil-Packed Metals & Evaporation Materials

1. Why are some metals packed in oil while others aren’t?

Only metals that are highly reactive or sensitive to oxidation require oil-based protection.

2. Can I use ultrasonic cleaning to remove the oil?

Yes, with compatible solvents. Avoid overly aggressive settings that may damage fine powders or fragile pellets.

3. What type of oil is used by most suppliers?

High-purity mineral oil or paraffin oil. These are inert and easy to clean.

4. Will oil affect my vacuum deposition process?

Not if it’s cleaned off properly. Any residue could otherwise compromise vacuum quality or film purity.

5. Can powders self-ignite if not packed in oil?

Yes. Ultra-fine powders like magnesium or zirconium can oxidize or even combust spontaneously in air.

6. What’s the shelf life of oil-packed materials?

Indefinite when stored properly. However, they should be used within 1 year for best performance.

7. How do I know if oil is still protecting the product?

Check for consistent coating. If it looks dried out or patchy, contact your supplier.

8. Can I specify a different packing method?

Yes. At MetalsTek, we offer nitrogen-filled or vacuum-sealed options on request.

9. Is oil packaging accepted by customs for international shipping?

Yes, as long as it’s properly declared and conforms to IATA shipping standards.

10. Can oil leave behind carbon contamination?

If improperly cleaned, yes. Always degrease before use in cleanroom or deposition settings.

Conclusion

If you’re working with advanced materials, don’t be surprised when they arrive oily—that layer of protection could be the difference between flawless performance and costly failures. At MetalsTek, we treat every shipment like a precision component because, well, it is.

📩 Want a quote or need custom packaging advice? Reach out at sales@metalstek.com

Or visit us at www.metalstek.com for more advanced materials engineered for performance.