Introduction

In an age dominated by advanced alloys, composites, and engineered ceramics, Lead Round Bar may seem like a material from another era. Yet behind hospital walls, inside nuclear facilities, and deep within chemical plants, lead continues to perform tasks that few modern materials can replicate.

Its strength is not in speed or stiffness, but in mass, stability, and reliability. Lead does not compete—it absorbs, shields, dampens, and protects. For engineers and scientists who work with radiation, aggressive chemicals, or vibration-sensitive systems, lead round bars remain a deliberate and highly practical choice.

This article explores why Lead Round Bar continues to play a critical role in modern industry, what makes it uniquely effective, and why it still deserves a place in contemporary material selection.

The Quiet Power of Density

One defining characteristic sets lead apart immediately: density.

At approximately 11.34 g/cm³, lead packs more mass into a smaller volume than most industrial metals. This single property explains much of its enduring value.

High density allows lead round bars to:

- Absorb X-ray and gamma radiation efficiently

- Act as compact counterweights where space is limited

- Dampen vibration and mechanical noise

- Provide stability without structural complexity

Unlike materials that rely on complex microstructures or coatings, lead’s effectiveness comes from physics itself—its atomic weight and packing efficiency.

Designed to Shield, Not to Show Off

Lead is not chosen for appearance or mechanical strength. It is chosen because it does its job quietly and predictably.

Radiation Shielding Excellence

number enables strong interaction with ionizing radiation, making it indispensable in:

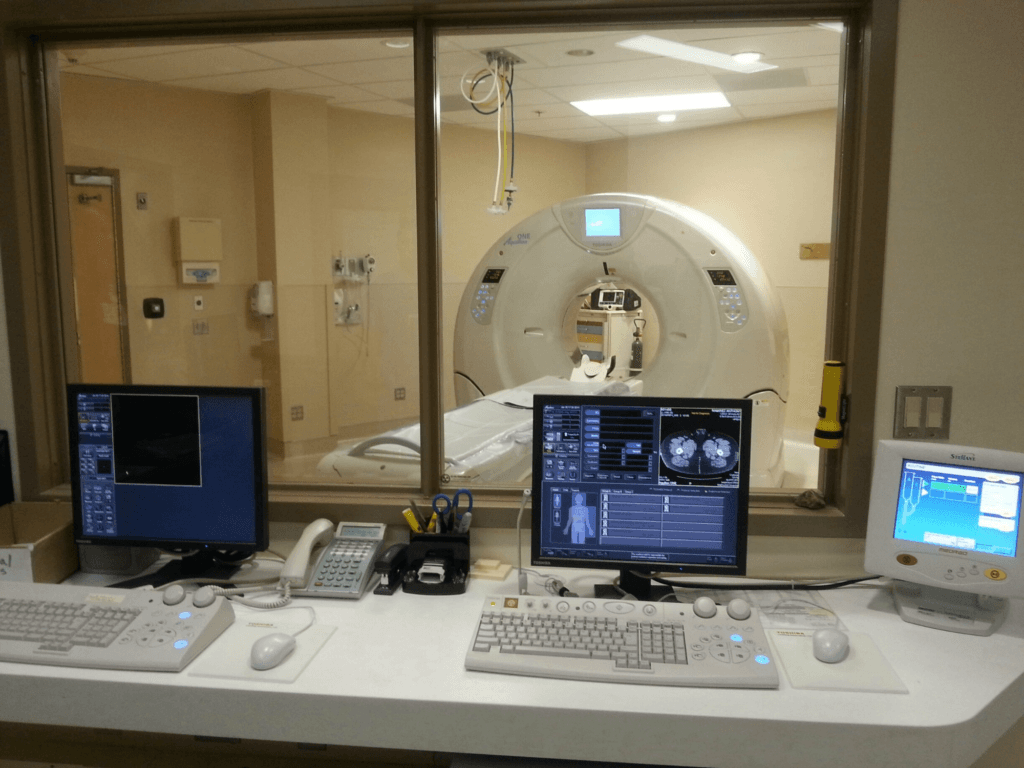

Medical imaging rooms (CT, X-ray, radiotherapy)

Nuclear research and isotope handling

Industrial non-destructive testing (NDT)

Scientific laboratories and shielding assemblies

Round bar geometry allows engineers to machine precise shielding components, modular inserts, or movable protection systems—far more flexible than flat sheets alone.

Chemical Resistance Where Others Fail

Lead’s chemical behavior is often underestimated. In reality, lead offers exceptional resistance to many corrosive environments, especially acids.

Lead round bars are commonly used in:

- Sulfuric acid processing equipment

- Electrochemical systems and electrodes

- Battery manufacturing fixtures

- Acid-resistant supports and connectors

In these environments, lead forms a stable protective layer that slows further corrosion, providing long service life where stainless steels or aluminum may degrade rapidly.

A Material That Absorbs Energy—Literally

One of lead’s most overlooked advantages is its internal damping capacity.

Unlike rigid metals that transmit vibration, lead absorbs mechanical energy. This makes Lead Round Bars ideal for:

- Precision counterweights

- Rotating machinery balancing

- Noise reduction components

- Stability elements in sensitive instruments

For engineers battling resonance or vibration-induced wear, lead offers a simple, passive solution—no electronics, no tuning, no active control systems.

Machinability That Accelerates Prototyping

Lead’s softness and ductility make it one of the easiest metals to machine.

This property is especially valuable in:

- Research and development environments

- Custom shielding prototypes

- One-off industrial components

- Rapid modification or adjustment tasks

Complex shapes, tight fits, and quick revisions can be achieved without specialized tooling—saving time and cost during early-stage development.

Typical Technical Characteristics

| Parameter | Typical Value / Range | Why It Matters |

|---|---|---|

| Purity | ≥99.9% | Ensures predictable shielding and corrosion behavior |

| Density | ~11.34 g/cm³ | Core property for radiation absorption |

| Diameter Range | 5 – 200 mm (custom available) | Flexible integration into assemblies |

| Length | Up to 3000 mm | Reduces joints and installation complexity |

| Melting Point | 327 °C | Enables efficient casting and forming |

These properties make lead round bars function-first materials, selected for reliability rather than mechanical performance.

Lead vs. Modern Alternatives

| Material | Strength | Cost | Machinability | Shielding Efficiency |

|---|---|---|---|---|

| Lead | Low | Low | Excellent | Excellent |

| Tungsten | Very High | Very High | Difficult | Excellent |

| Steel | High | Moderate | Good | Poor |

| Copper | Moderate | High | Good | Limited |

While tungsten offers superior density, its cost and machining difficulty often limit its use to compact or extreme applications. Lead remains the most economical and practical solution for large-volume shielding and damping needs.

Handling Responsibility and Industrial Reality

Lead is a regulated material, and responsible handling is essential. In industrial settings, proper procedures—protective equipment, sealed assemblies, and controlled environments—ensure safe and compliant use.

For professional users, lead is not a hazard—it is a managed engineering material, well understood and effectively controlled.

Packaging & Supply Reliability

Lead Round Bars supplied by Metalstek are clearly labeled, securely packaged, and protected against deformation during storage and transport. Packaging solutions are designed to maintain material integrity while meeting international shipping and regulatory requirements.

Conclusion: A Material That Endures Because It Works

Lead Round Bar is not trendy. It does not promise breakthrough performance or futuristic design. What it offers instead is certainty.

When radiation must be blocked, vibration must be absorbed, or corrosive environments must be survived, lead delivers—consistently, economically, and predictably.

That is why, despite centuries of material innovation, lead round bars remain firmly embedded in modern industry.