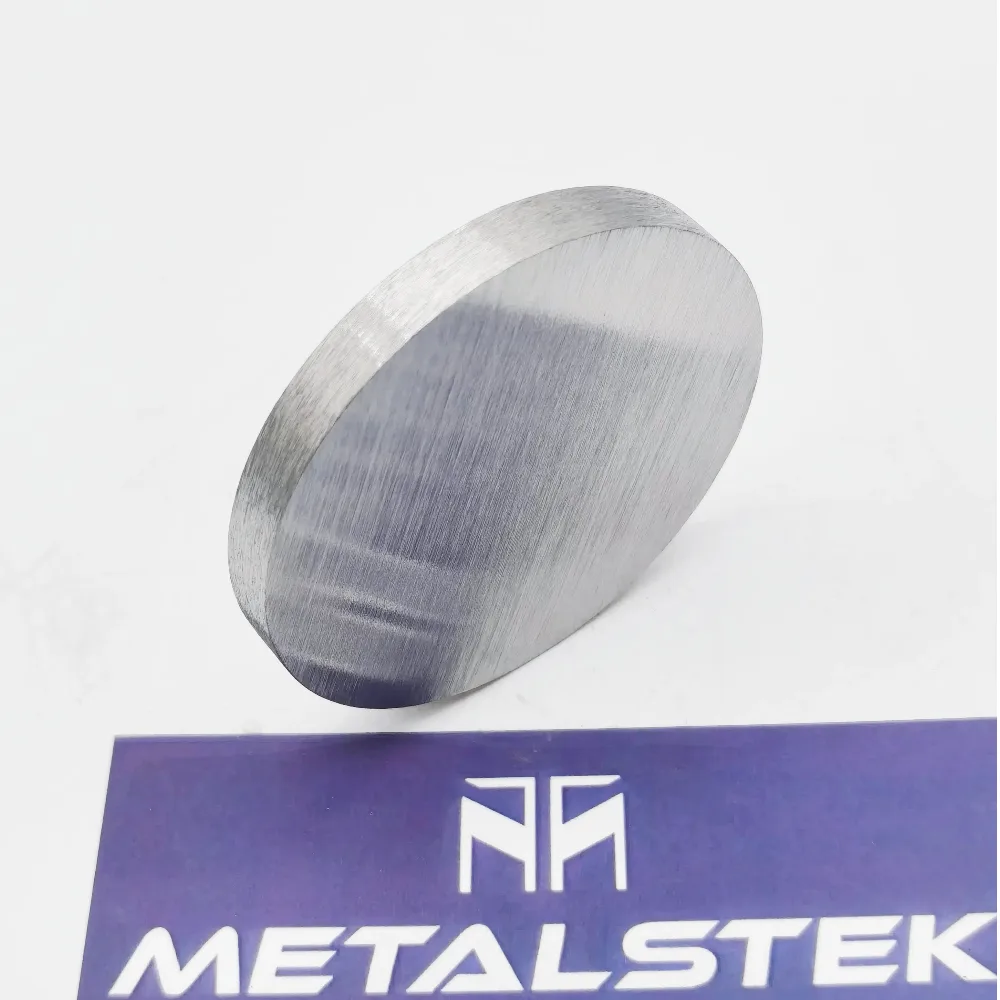

For applications requiring yttrium thin films with minimal downtime and clean vacuum performance, a magnetic keeper (mag‑keeper) mounting system offers an elegant solution. MetalsTek supplies high-purity yttrium targets engineered for mag‑keeper retention—enabling tool‑free target swaps while maintaining excellent thermal contact and stability.

Yttrium is widely used in optical coatings, rare-earth oxide films (like yttria), and as a dopant in various semiconductor and ceramic systems. Paired with a mag‑keeper system, it becomes easier to manage target changes, reduce particulate sources, and streamline sputtering chamber maintenance.

Key Features & Material Properties

Below is a reference table with yttrium properties and target design parameters. Use your batch data for final values.

| Parameter | Typical / Reference Value | Notes / Design Relevance |

|---|---|---|

| Purity | 99.9 % (3N) to 99.999 % (5N) | Higher purity reduces contamination in films |

| Density | ≈ 4.47 g/cm³ | Influences thermal mass, backing design (from vendor spec) |

| Melting Point | ~ 1526 °C | Key for thermal management during high power sputtering |

| Boiling Point / Vaporization | ~3336–3338 °C | Upper thermal budget limit |

| Thermal Conductivity | ~17.2 W/m·K | Governs heat spread in target (vendor spec) |

| Coefficient of Thermal Expansion | ~10.6 × 10⁻⁶ /K | Useful for matching backing and magnet materials |

| Sputter Compatibility | DC, RF | Y is conductive, so DC or RF sputtering is generally viable |

| Maximum Power Density (Unbonded) | ~30 W/in² (reference) | Typical upper rating for yttrium targets in some designs |

Magnetic Keeper Design Notes:

- Magnetic holding assemblies are sized to generate sufficient attractive force without interfering with the plasma.

- Backing plates must remain nonmagnetic (or magnet‑friendly) and provide good heat conduction.

- Interface surfaces need planarity and conductive contact; thin coupling layers may be used.

- The magnetic circuit must be designed so that removal/attachment of the target is smooth and reliable.

Applications & Benefits

- Optical coatings & dielectric layers: Yttrium is used in yttria, oxide films, and transparent layers in advanced optics

- Doped layers / buffer layers: As a component in multilayer stacks or doping agents

- High-throughput manufacturing: With mag‑keeper mounts, downtime is reduced for target swaps

- Reduced particulate risk: Absence of mechanical clamps or screws lowers potential contamination sources

- Flexible target maintenance: Easier cleaning, replacement, or inspection without tools

Design & Operational Considerations

- Ensure magnet force is balanced: strong enough for contact, but not so strong it hinders removal or causes misalignment

- Thermal paths must be optimized: magnetic retention points should also serve as thermal conduction paths

- Calibrate for expansion: any thermal cycling should not loosen contact or cause warping

- Ramp power gradually: avoid thermal shock during start-up or shutdown

- Use protective packaging: targets should be sealed to avoid oxidation or contamination before installation

You May Also Want to Know

1. What is a magnetic keeper (mag-keeper)?

It’s a magnetic mounting system that holds a sputtering target in place using strong magnets, eliminating mechanical clamps or bolts.

2. Can yttrium be used with mag-keeper systems?

Yes. With the correct thermal and magnetic design, yttrium targets work perfectly in mag-keeper setups and benefit from faster installation.

3. What purity levels are available for yttrium targets?

MetalsTek offers 99.9% (3N), 99.99% (4N), and 99.999% (5N) purity levels to support a wide range of film quality demands.

4. What are the standard shapes for yttrium sputtering targets?

Circular discs and rectangular plates are most common, but we can manufacture to your specific geometry, including notched or slotted forms.

5. What backing materials are used in mag-keeper yttrium targets?

Typically copper or molybdenum. These provide thermal conduction while remaining compatible with the magnetic field design.

6. What are the thermal considerations in mag-keeper targets?

Contact surfaces must be flat and conductive. We use optimized bonding techniques and surface finish controls to maintain good heat flow.

7. Does mag-keeper design reduce particles?

Yes. Removing physical clamps or screws eliminates one of the main sources of particulate contamination during target installation and operation.

8. How fast can I swap yttrium targets in a mag-keeper setup?

In many systems, target swaps take less than 2 minutes. Just detach magnetically and install the new target — no tools required.

9. Are there risks in using mag-keeper designs?

Poor magnetic contact, improper field design, or uneven surfaces can affect heat transfer or alignment. That’s why MetalsTek builds and tests every target to spec.

10. What is the lead time for yttrium mag-keeper targets?

Generally 2–4 weeks depending on quantity, size, and bonding needs. We accommodate urgent runs when needed.

11. How do I clean a yttrium target before use?

If vacuum-packed, use dry nitrogen or argon glovebox to open. If oil-packed, clean with high-purity alcohol and dry before chamber loading.

12. Can I request target + magnet assembly together?

Yes. We can supply yttrium targets pre-mounted or matched to your system drawings.

13. Are these compatible with both DC and RF sputtering?

Yes. Yttrium’s conductivity supports both DC and RF modes, depending on the chamber configuration.

14. What sputtering rates can I expect with yttrium?

Rates depend on power density and pressure, but yttrium typically offers moderate to fast deposition speeds in both oxide and metal modes.

15. What chamber conditions are ideal for yttrium sputtering?

Clean vacuum (10⁻⁶ torr range), stable power input, and proper shielding will optimize performance and film quality.

16. Can mag-keeper designs be retrofitted to old cathodes?

Yes, but it depends on the cathode design. We can help evaluate your hardware and offer a fit-up design or adapter if needed.

17. What safety precautions apply to magnetic keeper systems?

Magnets can pinch, attract tools, or affect electronics. Use gloves, non-metallic tools, and avoid fast hand movements near the field.

18. How long does a yttrium target last?

Depends on deposition rate, power load, and film thickness needs. Typical lifespans range from tens to hundreds of hours.

19. How is target bonding done?

We offer indium bonding or diffusion bonding depending on temperature needs, ensuring maximum thermal contact and structural strength.