1. Introduction to Zirconium Sheet and Foil

Zirconium (Zr) is a high-performance transition metal that plays a critical role in industries where corrosion resistance, chemical stability, and reliability under extreme conditions are essential. Although zirconium is less widely used than titanium or nickel alloys, it occupies a unique position in applications where other metals fail.

Zirconium Sheet and Zirconium Foil represent two of the most important processed forms of zirconium metal. Typically produced from high-purity zirconium sponge through vacuum melting and precision rolling, these materials are widely valued for their exceptional performance in chemical processing, nuclear technology, energy systems, electronics, and advanced research.

What distinguishes zirconium from many other metals is its rare combination of:

- Outstanding resistance to strong acids and corrosive chemicals

- Excellent stability in high-temperature water and steam

- Extremely low neutron absorption cross-section

- Good ductility and formability

- High chemical inertness and purity

These characteristics define the application boundaries of zirconium sheet and foil, positioning them as specialty materials rather than commodity metals.

2. Chemical Processing and Corrosion-Resistant Equipment

2.1 Performance in Aggressive Chemical Environments

The chemical processing industry represents one of the largest and most established application areas for zirconium sheet. Zirconium exhibits superior resistance to many corrosive media that rapidly attack stainless steels, titanium, and nickel-based alloys.

Zirconium sheet performs exceptionally well in:

- Hydrochloric acid (HCl) across a wide concentration range

- Sulfuric acid (H₂SO₄), including high-temperature conditions

- Nitric acid (HNO₃) and mixed acid systems

- Organic acids and halogen-containing compounds

Unlike titanium, which suffers rapid corrosion in hydrochloric acid, zirconium maintains a stable passive oxide layer that prevents localized corrosion such as pitting and crevice attack.

2.2 Typical Chemical Industry Applications

In industrial practice, zirconium sheet is widely used as a corrosion-resistant lining or structural material in critical equipment, including:

- Chemical reactors and pressure vessels

- Heat exchanger tube sheets and end plates

- Distillation columns and internal components

- Acid storage tanks and transport vessels

To optimize cost and mechanical strength, zirconium sheet is often applied as a clad or bonded layer over carbon steel or stainless steel substrates using explosion bonding or welding techniques. This approach delivers long service life while controlling overall system cost.

3. Pharmaceutical and Fine Chemical Manufacturing

3.1 Purity and Contamination Control

In pharmaceutical and fine chemical production, material selection is driven not only by corrosion resistance but also by purity, cleanliness, and process stability. Even trace metal contamination can compromise product quality or regulatory compliance.

Zirconium sheet offers several advantages in these environments:

- Minimal metal ion release into process media

- High resistance to repeated cleaning and sterilization cycles

- Compatibility with aggressive catalysts and intermediates

These properties make zirconium sheet suitable for high-value synthesis processes where equipment integrity and material inertness are critical.

3.2 Application Scenarios in Pharma and Specialty Chemicals

Common applications include:

- Reactor linings for acidic synthesis steps

- Components in catalytic reaction systems

- High-purity distillation and separation equipment

- Specialized acid handling systems

Compared with high-nickel alloys, zirconium often provides longer service life in specific acidic environments while reducing the risk of product contamination.

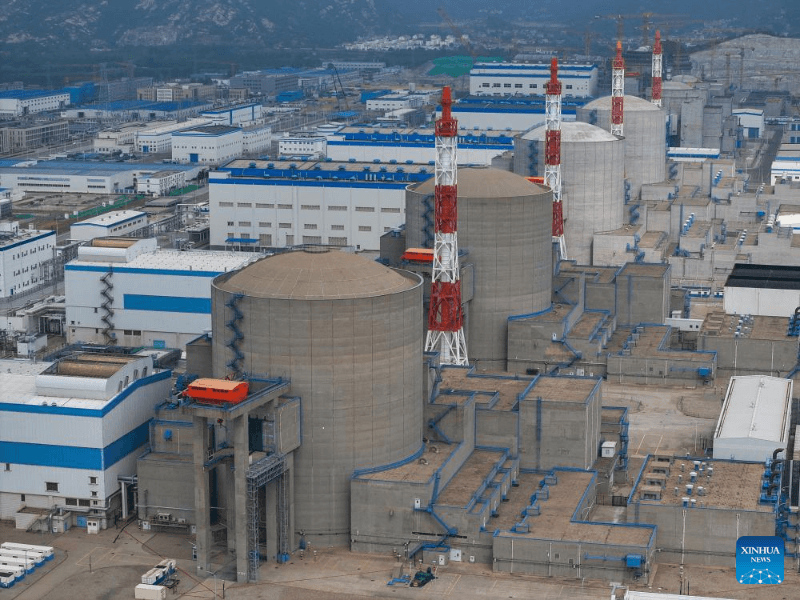

4. Nuclear Industry and Nuclear Energy Systems

4.1 Strategic Importance of Zirconium in Nuclear Technology

Zirconium occupies a unique and irreplaceable position in the nuclear industry due to its exceptionally low thermal neutron absorption cross-section. This property allows zirconium-based materials to remain in the reactor core without significantly interfering with the nuclear reaction.

While zirconium alloys are most commonly associated with nuclear fuel cladding, high-purity zirconium sheet and foil are also essential in nuclear-related systems and research environments.

4.2 Applications of Zirconium Sheet and Foil in Nuclear Systems

Zirconium sheet and foil are used in:

- Structural components in research reactors

- Experimental reactor assemblies

- Isolation plates and shielding components

- Nuclear fuel fabrication and inspection tooling

In these applications, zirconium sheet must meet stringent requirements for:

- Impurity control (oxygen, nitrogen, carbon, iron)

- Hafnium content reduction

- Microstructural uniformity

- Welding reliability and hydrogen resistance

These demanding specifications make nuclear-grade zirconium sheet a high-barrier, high-value material.

5. Energy Systems and High-Temperature Water Applications

5.1 High-Pressure and High-Temperature Water Environments

Zirconium demonstrates excellent stability in high-temperature water and steam environments, which are commonly encountered in advanced energy systems. Unlike many alloys that suffer oxidation or stress corrosion cracking, zirconium maintains structural integrity over long operating periods.

Typical applications include:

- High-pressure water reaction systems

- Supercritical water oxidation (SCWO) equipment

- Specialized thermal and chemical energy devices

In these systems, zirconium sheet is often used as a liner, separator, or corrosion-resistant barrier.

5.2 Emerging Applications in Hydrogen and Advanced Energy Research

With the growth of hydrogen energy and advanced chemical energy systems, zirconium foil is gaining interest for its:

- Chemical inertness

- Thin, controllable thickness

- Stability under reactive conditions

Zirconium foil is used in experimental electrochemical devices, reaction separators, and interface layers where conventional metals degrade rapidly.

6. Electronics, Semiconductor, and Thin Film Technology

6.1 Zirconium Foil in Thin Film Deposition Processes

In electronics and semiconductor manufacturing, zirconium foil is primarily used as a process material rather than a final product. It serves as a source or intermediate material in vacuum deposition technologies such as:

- Electron beam evaporation

- Thermal evaporation

- Reactive deposition processes

Zirconium-based films, particularly zirconium oxide (ZrO₂), are widely used for:

- High-k dielectric layers

- Protective and wear-resistant coatings

- Optical and functional thin films

6.2 Research and Development in Microelectronics

In microelectronics, MEMS, and sensor research, zirconium foil is valued for:

- Uniform composition

- Good formability for micro-fabrication

- Stable surface chemistry

Zirconium foil is commonly employed in laboratory-scale experiments, prototype fabrication, and advanced materials research where performance validation is required before scaling.

7. Medical, Biological, and Scientific Research Applications

7.1 Biocompatibility and Chemical Stability

Zirconium and its oxides are well known for their biocompatibility. While zirconium sheet and foil are not typically used directly in implantable devices, they play supporting roles in:

- Medical equipment components

- High-purity laboratory containers

- Corrosion-resistant research tools

Their chemical inertness ensures long-term stability in biological and chemical environments.

7.2 Laboratory and Scientific Equipment

In research laboratories, zirconium sheet and foil are frequently used in:

- High-purity reaction vessels and liners

- Vacuum and inert-atmosphere systems

- Experimental setups requiring extreme corrosion resistance

In these settings, material traceability, batch consistency, and purity are often more important than cost.

8. Comparison Between Zirconium Sheet and Zirconium Foil

| Aspect | Zirconium Sheet | Zirconium Foil |

|---|---|---|

| Typical Thickness | ≥ 0.5 mm | ≤ 0.2 mm |

| Primary Function | Structural and lining material | Functional and process material |

| Main Industries | Chemical, nuclear, energy | Electronics, R&D, thin films |

| Production Volume | Medium to large sizes | Small batches, high value |

| Key Technical Focus | Corrosion resistance, welding | Purity, uniformity, surface quality |

This distinction highlights how form factor directly determines application scope within zirconium material systems.

9. Future Outlook and Conclusion

Zirconium Sheet and Foil are not general-purpose metals; they are application-driven, high-performance materials selected only when operating conditions demand exceptional reliability. Their usage is concentrated in environments where failure is unacceptable and material substitution is limited.

Key trends shaping future demand include:

- Continued investment in chemical processing infrastructure

- Long-term development of nuclear energy and nuclear research

- Growth in advanced energy and hydrogen technologies

- Expansion of semiconductor and thin-film research

Although the overall market size for zirconium sheet and foil remains relatively small, these materials occupy a strategic niche characterized by high technical barriers, strong customer loyalty, and long service lifecycles.

For manufacturers, researchers, and system designers, zirconium sheet and foil represent materials of choice when performance, safety, and durability take priority over cost.