Introduction

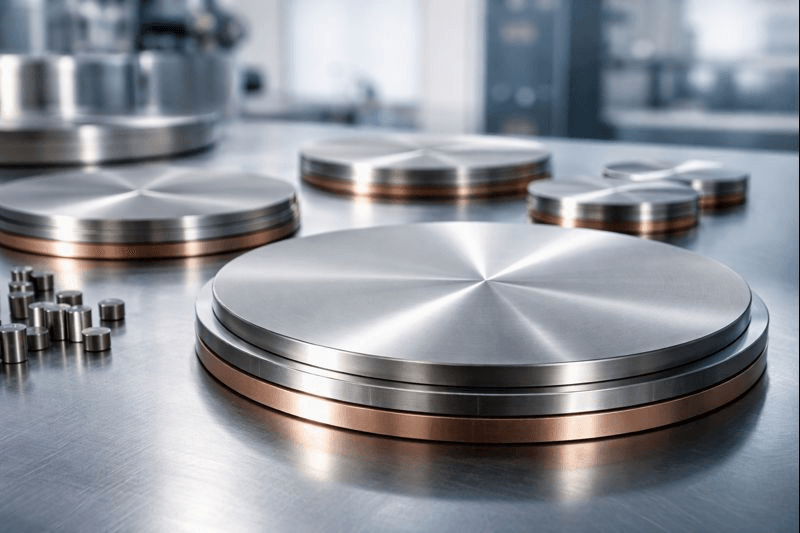

Molybdenum Rhenium (MoRe) sputtering targets occupy a unique and increasingly important position in advanced thin-film deposition technologies. By alloying molybdenum with a controlled amount of rhenium, the resulting material overcomes several intrinsic limitations of pure molybdenum—most notably brittleness, limited ductility at room temperature, and constraints in certain high-stress or high-temperature thin-film applications.

MoRe sputtering targets are widely adopted in research laboratories, semiconductor fabrication, superconducting electronics, aerospace micro-devices, and emerging quantum technologies. Their value lies not only in their high melting point and excellent thermal stability, but also in their superior mechanical robustness, tunable electrical resistivity, and enhanced thin-film reliability under extreme operating conditions.

This article provides a comprehensive and application-oriented analysis of the primary usage scenarios for Molybdenum Rhenium sputtering targets, with a focus on why MoRe is selected over pure molybdenum or other refractory alloys in each case.

Material Background: Why Molybdenum Rhenium?

Before examining applications, it is important to understand the material characteristics that drive MoRe’s adoption.

Pure molybdenum is well known for its:

- High melting point (~2623 °C)

- Excellent thermal conductivity

- Low vapor pressure

- Good chemical stability in vacuum

However, it also suffers from:

- Brittleness at room temperature

- Limited formability

- Sensitivity to grain boundary cracking during thermal cycling

By adding rhenium (typically 5–50 wt%), the alloy exhibits:

- Significantly improved ductility and toughness

- Reduced brittle-to-ductile transition temperature

- Improved resistance to thermal shock

- Enhanced stability of thin films under mechanical and thermal stress

These improvements make MoRe sputtering targets especially suitable for demanding thin-film environments where both electrical performance and long-term film integrity are critical.

Semiconductor and Microelectronics Applications

1. Thin-Film Electrodes and Interconnect Layers

One of the most established application scenarios for MoRe sputtering targets is the deposition of conductive thin-film electrodes and interconnects in semiconductor and microelectronic devices.

MoRe thin films offer:

- Stable electrical resistivity across a wide temperature range

- Strong adhesion to substrates such as silicon, sapphire, and compound semiconductors

- Good compatibility with standard photolithography and etching processes

Compared with pure molybdenum films, MoRe films show:

- Lower risk of cracking during thermal cycling

- Better stress management in multilayer device stacks

- Improved reliability in back-end-of-line (BEOL) processes

As device geometries continue to shrink and process temperatures increase, these properties become increasingly valuable.

2. High-Temperature Metallization Layers

In advanced semiconductor processes—especially power electronics and wide-bandgap devices (SiC, GaN)—metallization layers must withstand elevated temperatures during fabrication and operation.

MoRe sputtered films are frequently used as:

- Gate electrodes

- Diffusion barriers

- High-temperature contact layers

Their high melting point and resistance to interdiffusion help maintain electrical stability even under prolonged thermal stress, making them suitable for harsh-environment electronics.

Superconducting and Quantum Device Applications

3. Superconducting Thin Films

One of the most critical and rapidly expanding application areas for MoRe sputtering targets is superconducting electronics.

Certain MoRe compositions (commonly MoRe 50/50 or MoRe 60/40 atomic ratios) exhibit:

- Superconducting transition temperatures (Tc) in the range of 8–15 K

- Excellent film uniformity when deposited by magnetron sputtering

- Compatibility with standard nanofabrication techniques

As a result, MoRe thin films are widely used in:

- Superconducting nanowire single-photon detectors (SNSPDs)

- Josephson junctions

- Microwave kinetic inductance detectors (MKIDs)

- Quantum computing circuits

Compared with alternative superconducting materials (such as Nb or NbN), MoRe films often provide:

- Better mechanical robustness

- Reduced film stress

- More forgiving deposition conditions

4. Quantum Information and Cryogenic Electronics

In quantum devices, material stability at cryogenic temperatures is as important as electrical performance.

MoRe sputtered films demonstrate:

- Stable superconducting properties over repeated thermal cycling

- Strong adhesion to substrates at cryogenic temperatures

- Reduced defect formation compared with brittle refractory films

These advantages make MoRe sputtering targets a preferred choice in research and pilot-scale production of quantum sensors and quantum information processing hardware.

Aerospace and Extreme-Environment Micro-Devices

5. Thin-Film Components for Aerospace Sensors

Aerospace systems often operate in environments involving:

- Extreme temperature gradients

- High vacuum

- Mechanical vibration

- Radiation exposure

MoRe thin films are used in:

- Thin-film strain gauges

- Temperature sensors

- Micro-heaters

- Protective conductive layers

The Mo-Re alloy’s resistance to thermal fatigue and cracking allows deposited films to remain functional where many conventional metal films would fail.

6. High-Temperature MEMS and Micro-Actuators

Micro-electromechanical systems (MEMS) designed for harsh environments require electrode and structural films that retain performance under stress.

MoRe sputtered layers are employed in:

- MEMS actuators operating at elevated temperatures

- Micro-heaters and thermal actuators

- Structural layers requiring both conductivity and mechanical strength

The improved ductility introduced by rhenium reduces the likelihood of micro-cracking during actuation cycles, significantly extending device lifetime.

Thin-Film Research and Advanced Materials Development

7. Research-Grade Thin-Film Deposition

In academic and industrial R&D, MoRe sputtering targets are widely used for exploratory thin-film studies.

Researchers value MoRe for:

- Tunable electrical and mechanical properties via composition control

- Repeatable sputtering behavior

- Compatibility with RF and DC magnetron sputtering systems

MoRe targets are frequently selected when:

- Studying stress-engineered thin films

- Investigating high-temperature thin-film phase stability

- Developing next-generation refractory alloy coatings

8. Multilayer and Heterostructure Systems

MoRe films are commonly integrated into complex multilayer stacks, including:

- Metal/insulator/metal (MIM) structures

- Superlattice architectures

- Diffusion-barrier systems

Their chemical stability and low reactivity help preserve sharp interfaces, which is essential for reliable device performance at the nanoscale.

Optical and Functional Coating Applications

9. Infrared and Functional Coatings

While not primarily an optical material, MoRe thin films are sometimes used in:

- Infrared-reflective coatings

- Functional layers requiring controlled emissivity

- High-temperature optical components

Their stable electrical and thermal behavior allows designers to fine-tune functional properties without sacrificing durability.

Manufacturing and Process Advantages of MoRe Sputtering Targets

Beyond application performance, MoRe sputtering targets offer several practical benefits during deposition:

- Stable sputtering rates across long production runs

- Reduced risk of target cracking compared with pure molybdenum

- Compatibility with bonded or monolithic target designs

- Consistent film composition, even at higher sputtering powers

These factors make MoRe targets suitable for both laboratory-scale research and small-to-medium volume industrial production.

Typical MoRe Compositions and Selection Considerations

Common MoRe sputtering target compositions include:

- Mo-5Re / Mo-10Re: Improved ductility with properties close to pure Mo

- Mo-25Re / Mo-30Re: Balanced mechanical and electrical performance

- Mo-50Re: Superconducting applications and cryogenic devices

Target selection depends on:

- Required electrical resistivity or superconducting behavior

- Operating temperature range

- Mechanical stress tolerance

- Deposition system configuration

Conclusion

Molybdenum Rhenium sputtering targets represent a highly versatile solution for advanced thin-film applications where conventional refractory metals reach their limits. By combining the high-temperature strength of molybdenum with the ductility and stability provided by rhenium, MoRe targets enable reliable thin-film deposition across semiconductor, superconducting, aerospace, MEMS, and quantum technology sectors.

Their growing adoption reflects broader trends in modern materials engineering: higher operating temperatures, greater mechanical demands, tighter device tolerances, and increasing reliance on multifunctional thin films. For researchers and engineers seeking a robust, high-performance sputtering material with proven reliability under extreme conditions, MoRe sputtering targets remain a compelling and future-ready choice.

For detailed specifications, composition options, and a quotation tailored to your deposition system, please contact us at sales@metalstek.com.