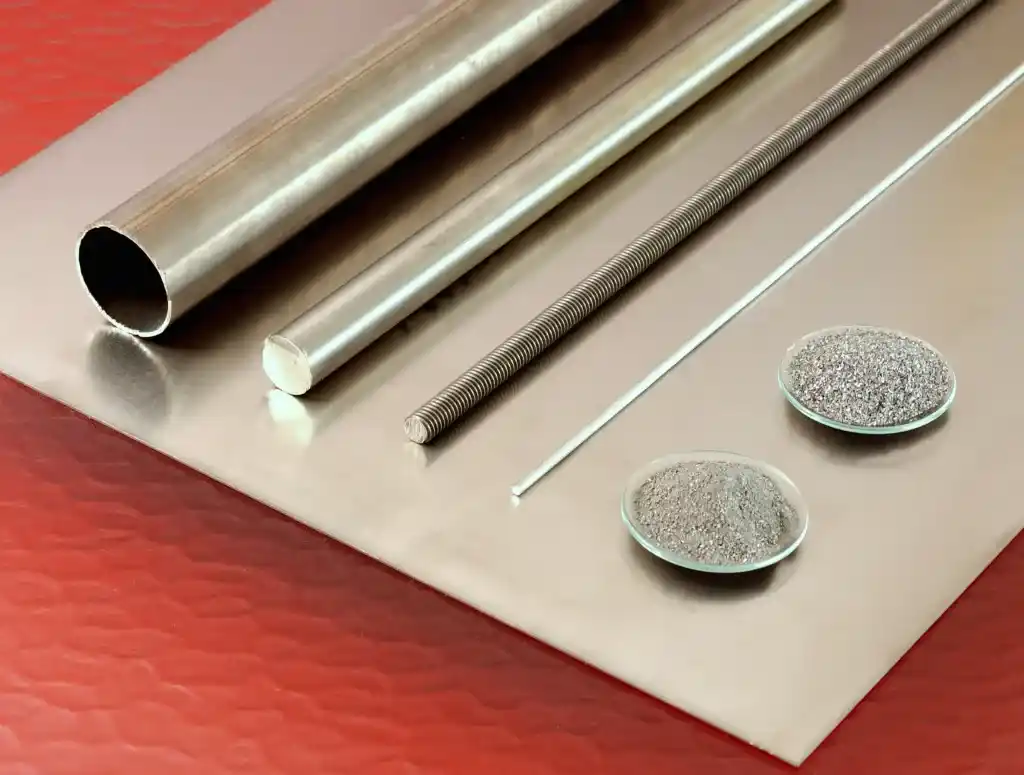

When it comes to choosing the right material for durable and strong products, two heavyweights often come to mind: Titanium and Stainless Steel. Both metals possess remarkable strength and resilience, making them popular choices in various industries and applications. But which one comes out on top in the ultimate battle of strength and durability?

In this article, we will compare titanium and stainless steel and duplex stainless steel, examining their unique properties, advantages, and limitations. Whether you’re in the market for a new watch, jewelry, or even surgical instruments, understanding the differences between these two metals can help you make an informed decision.

Titanium, known for its exceptional strength-to-weight ratio, offers unparalleled lightweight performance and corrosion resistance. On the other hand, stainless steel boasts great strength, remarkable toughness, and affordability. But there’s more to it than meets the eye. We will delve into each material’s characteristics, discussing their applications, maintenance requirements, and even environmental impact.

Join us as we embark on this journey to uncover which metal reigns supreme in the battle of strength and durability – titanium or stainless steel. Let’s discover the fascinating world of these formidable materials and make an educated choice for our next purchase.

Properties and characteristics of Titanium

Titanium is a lightweight metal known for its exceptional strength-to-weight ratio. It is approximately 45% lighter than steel but possesses similar strength. This unique property makes it a favored material in industries where weight reduction is crucial, such as aerospace engineering and sports equipment manufacturing.

In addition to its lightweight nature, titanium is highly corrosion-resistant. It forms a protective oxide layer on its surface when exposed to air or moisture, preventing rust and degradation. This resistance to corrosion makes it an ideal choice for applications in marine environments or medical implants, where durability is paramount.

Furthermore, titanium has excellent biocompatibility, meaning it is well-tolerated by the human body. This property has made it a popular choice in the medical field for surgical implants and prosthetics. Titanium’s ability to fuse with bone, known as osseointegration, ensures a strong and stable connection between the implant and the surrounding tissue.

Despite its many advantages, titanium does have some limitations. It is a relatively expensive material compared to stainless steel, which can be a deterrent for cost-sensitive applications. Additionally, titanium is challenging to work with due to its high melting point and low thermal conductivity. This can increase the manufacturing cost and complexity of products made from titanium.

In summary, titanium’s lightweight nature, corrosion resistance, and biocompatibility make it an excellent choice for applications that require strength, durability, and reduced weight. Its use in aerospace, medical, and sports industries is a testament to its remarkable properties.

Properties and characteristics of Stainless Steel

Stainless steel, a popular choice in various industries, boasts great strength, remarkable toughness, and affordability. It is an alloy composed primarily of Iron, with a small percentage of Chromium and other elements such as Nickel and Molybdenum that enhance its properties. The addition of chromium, in particular, gives stainless steel its signature corrosion resistance by forming a passive oxide layer on its surface, similar to titanium. This makes stainless steel an excellent choice for environments where exposure to moisture and chemicals is common, such as in kitchen appliances, cutlery, and industrial equipment.

One of stainless steel’s most notable characteristics is its impressive strength and durability. Unlike titanium, stainless steel is significantly denser, which contributes to its robustness. This density translates to superior impact resistance and the ability to withstand heavy loads, making it a preferred material in construction, automotive, and heavy machinery industries.

Moreover, stainless steel is highly versatile and comes in various grades and finishes, each tailored to specific applications. For instance, the austenitic grades, such as 304 and 316 stainless steel, are well-known for their excellent corrosion resistance and formability, making them ideal for use in the food and medical industries. Ferritic and martensitic grades, on the other hand, offer enhanced strength and wear resistance, suitable for automotive parts and cutting tools.

Another advantage of stainless steel is its affordability and ease of fabrication. Stainless steel can be readily welded, machined, and formed, which simplifies manufacturing processes and reduces costs. This economic efficiency, combined with its long lifespan and low maintenance requirements, makes stainless steel a cost-effective option for many applications.

However, stainless steel is not without its drawbacks. It is considerably heavier than titanium, which can be a disadvantage in applications where weight is a critical factor. Additionally, while stainless steel is corrosion-resistant, it is not entirely immune to corrosion and can suffer from pitting and crevice corrosion in highly saline or chlorinated environments.

In summary, stainless steel’s strength, versatility, and cost-effectiveness make it a popular choice across numerous industries. Its ability to withstand harsh conditions and its economic benefits underscore its widespread use in everything from household items to industrial machinery.

Strength and Durability Comparison between Titanium and Stainless Steel

When comparing the strength and durability of titanium and stainless steel, both materials exhibit impressive performance but in different ways. Titanium’s strength-to-weight ratio is unparalleled, meaning it can provide the same or greater strength as stainless steel at a significantly lower weight. This makes titanium an excellent choice for applications where reducing weight without sacrificing strength is essential.

On the other hand, stainless steel is denser and typically offers higher overall tensile strength and impact resistance compared to titanium. This makes stainless steel more suitable for applications that require maximum durability and the ability to withstand significant force or impact, such as construction materials and heavy machinery components.

Applications of Titanium in Various Industries

Titanium’s unique properties make it suitable for a variety of specialized applications across different industries:

- Aerospace: Titanium’s high strength-to-weight ratio and excellent corrosion resistance make it ideal for aircraft components, such as landing gear, jet engine parts, and structural frames.

- Medical: Due to its biocompatibility, titanium is commonly used for surgical implants, prosthetics, and dental implants. Its ability to bond with bone ensures a stable and long-lasting integration.

- Sports Equipment: Lightweight and durable, titanium is used in high-performance sports equipment, including golf clubs, bicycle frames, and tennis rackets.

- Marine: Titanium’s resistance to seawater corrosion makes it a preferred material for marine applications, such as ship components, underwater pipes, and offshore oil rigs.

Applications of Stainless Steel in Various Industries

Stainless steel’s versatility and durability allow it to be used in a wide range of applications:

- Construction: Stainless steel is widely used in construction for structural components, roofing, and cladding due to its strength and corrosion resistance.

- Automotive: Components such as exhaust systems, chassis, and trim are often made from stainless steel to ensure longevity and resistance to corrosion.

- Medical: Surgical instruments, hospital equipment, and implants are frequently made from stainless steel, particularly austenitic grades, for their hygiene and durability.

- Food and Beverage: Stainless steel is the material of choice for kitchen equipment, storage tanks, and processing machinery because it is easy to clean and resistant to corrosion.

Pros and Cons of Titanium

Pros:

- Exceptional strength-to-weight ratio

- High corrosion resistance

- Excellent biocompatibility

- Durable and long-lasting

Cons:

- Expensive compared to stainless steel

- Difficult to machine and work with

- Higher production costs due to complex manufacturing processes

Pros and Cons of Stainless Steel

Pros:

- High tensile strength and durability

- Cost-effective and readily available

- Versatile with various grades and applications

- Easy to fabricate and maintain

Cons:

- Heavier than titanium

- Prone to certain types of corrosion in extreme environments

- Lower strength-to-weight ratio compared to titanium

Which is Better: Titanium or Stainless Steel?

Determining which material is better depends largely on the specific requirements of the application. If weight reduction and corrosion resistance are paramount, titanium is the superior choice. It excels in aerospace, medical, and sports applications where these properties are critical.

Conversely, if cost, ease of fabrication, and overall strength are more important, stainless steel is the better option. It is widely used in construction, automotive, and household applications due to its durability and affordability.

Comparing Titanium with Duplex Stainless Steel

Titanium and duplex stainless steel each have unique properties that make them suitable for different uses. Titanium is celebrated for its exceptional strength-to-weight ratio and outstanding corrosion resistance. In contrast, duplex stainless steel provides a balanced mix of strength, toughness, and corrosion resistance, making it a versatile choice for many industries.

1. Composition and Structure

Titanium is primarily composed of titanium (Ti), sometimes alloyed with elements like aluminum and vanadium. Its hexagonal close-packed (HCP) crystal structure contributes to its remarkable strength and lightweight characteristics.

Duplex stainless steel is an alloy with a balanced mix of austenitic and ferritic phases, including elements such as chromium (Cr), nickel (Ni), and molybdenum (Mo). This dual-phase structure offers a unique combination of strength and corrosion resistance.

2. Mechanical Properties

Titanium is known for its high tensile strength and low density, making it perfect for applications requiring strong yet lightweight materials. It maintains its strength even at high temperatures, which is crucial for aerospace and high-performance industries.

Duplex stainless steel boasts a higher yield strength than regular austenitic stainless steels, combined with good ductility and toughness. This makes it ideal for heavy-duty applications where strength and toughness are paramount.

3. Corrosion Resistance

Titanium’s corrosion resistance is nearly unmatched, particularly in harsh environments like seawater and acidic conditions. This makes it the top choice for marine, chemical, and medical applications.

Duplex stainless steel also offers excellent corrosion resistance, especially in chloride-containing environments, which makes it a popular choice for chemical processing, oil and gas, and desalination plants.

4. Thermal Properties

Titanium has a lower thermal conductivity than duplex stainless steel, meaning it does not transfer heat as efficiently. However, its lower coefficient of thermal expansion ensures stability under temperature fluctuations.

Duplex stainless steel has higher thermal conductivity and can withstand significant temperature variations without losing structural integrity, making it advantageous for heat exchangers and pressure vessels.

5. Cost and Availability

Titanium is generally more expensive due to its complex extraction and processing methods. Its relative scarcity compared to stainless steel components impacts both its price and availability.

Duplex stainless steel, on the other hand, is more affordable and widely available, using more common elements. This makes it a cost-effective option for various industrial applications.

6. Applications

Titanium is extensively used in aerospace, medical implants, and chemical processing equipment due to its strength, lightweight, and corrosion resistance.

Duplex stainless steel is commonly found in chemical plants, the oil and gas industry, and construction, thanks to its excellent mechanical properties and cost efficiency.

In summary, choosing between titanium and duplex stainless steel depends on your specific needs. If you need a lightweight, high-strength material with unparalleled corrosion resistance, titanium is your best bet. However, if you require a robust, cost-effective solution with excellent corrosion resistance and mechanical properties, duplex stainless steel is the ideal choice. Understanding these differences will help you select the right material for your application, ensuring maximum performance and longevity.

Conclusion

Both titanium and stainless steel are formidable materials with distinct advantages and limitations. Understanding their properties and suitability for different applications is key to making an informed decision. Whether opting for the lightweight and corrosion-resistant nature of titanium or the robust and versatile qualities of stainless steel, choosing the right material will ensure optimal performance and value for your specific needs.

Related: Titanium, Stainless Steel

3 Replies to “Titanium vs. Stainless Steel & Duplex Steel: The Ultimate Battle of Strength and Durability”

Why wasn’t the duplex variant of stainless used as a comparison ?

Thank you for your advice. We hereby added this part: Comparing Titanium with Duplex Stainless Steel

This design is spectacular! You definitely know how to keep a

reader amused. Between your wit and your videos, I was almost moved to start my own blog (well, almost…HaHa!) Excellent job.

I really loved what you had to say, and more than that,

how you presented it. Too cool!